|

Precision Straight Edges |

| for Checking Airport Pavement Smoothness |

|

| |

|

|

|

|

|

| |

Rough Pavement is Hazardous to

Aircraft |

| |

The evolution of the straight edge for testing pavement

has roots in highway construction where smoothness affects the ride quality. Cars have suspension systems that

dampen road roughness. Aircraft suspension systems are not designed to absorb pavement roughness but to absorb

the energy of landing impact. This means that most of the available strut stroke is already used up when the aircraft

is on the ground. |

| |

| |

| |

|

|

|

|

|

| |

Runway pavement surface irregularities may cause vibrations

in the cockpit that make controls difficult to manipulate. Pavement profile irregularities can also cause increased

stress and premature failure of critical airplane components. Uneven pavement can reduce braking capacity as the

airplane responds to vertical acceleration. |

|

| |

|

| |

| |

|

|

|

|

|

| |

FAA Pavement Roughness Specifications |

| |

The FAA advisory circular AC 150/5370-10E of 9/30/2009 specifies the "Standards for Construction

of Airports" for both asphalt and concrete pavements. The final pavement acceptance criteria are listed below:

Bituminous Pavements: P-403 page 20

(4) Smoothness - "The final surface shall be free from roller marks.

The finished surfaces of each course of the pavement, except the finished surface of the final surface course,

shall not vary more than 3/8 inch when evaluated with a 16 foot straightedge. The finished surface of the final

surface course shall not vary more than 1/4

inch when evaluated with a 16 foot straightedge".

Concrete Pavement: P-501 page 29 (3)

Smoothness - "As soon as the concrete has hardened sufficiently,

the pavement surface shall be tested with a 16-foot (5 m) straightedge or other specified device. Surface smoothness

deviations shall not exceed 1/4 inch

(6 mm) from a 16-foot (5 m) straightedge

placed in any direction, including placement along and spanning any pavement joint edge". |

| |

| |

| |

| |

| |

| |

| |

| |

|

|

|

|

|

| |

FAA Smoothness

< 1/4 inch in 16 foot

|

| |

|

|

|

|

|

| |

The FAA expects both newly constructed or rehabilitated pavement to meet the above standard. The ICAO Tolerable

Limit is 3-mm (0.12-inch) in 3-meters (9.8 feet). There are also a few regional specifications that hold deviation

as low as 1/8 inch in 16-foot for paving and seal coating. |

| |

|

|

|

|

|

| |

Military Airfield Pavement Roughness

Specifications |

| |

The US Air Force specifies pavement roughness in Engineering

Technical Letter (ETL) 09-2:

"Contingency Airfield Pavement Specifications". The procedure for completed asphalt paving smoothness

is standard is indicated in section 410.4.9. Smoothness. |

| |

"After completion of the final rolling of a lot, the inspector will test the final wearing

surface with a 3.6-meter [12-foot] straightedge. Take measurements parallel to and across all joints at equal distances

along the joint not to exceed 7.6 meters [25 feet]. Record locations that fail the straightedge test. Use the tolerance

criteria in Table 410-4". This

table shows a specification as low as 1/8

inch in 12-feet for runways. |

|

| |

|

|

|

|

|

| |

USAF Smoothness

< 1/8 inch in 12 foot

|

| |

|

|

|

|

|

| |

Straight Edges are a Better Choice

than Profilers |

| |

The FAA allows several other electronic systems that use various types of profilers that use indicators

to simulate the results of the 16-foot

straight edge. Per FAA specifications

from - AC 150/5370-10E P-501-29 "Use of the profilograph to measure pavement smoothness is optional and will be approved

on a case-by-case basis. Use of a profilometer may not be practical for all construction." |

| |

| |

| |

| |

|

|

|

|

|

| |

Since these profilers are significantly much more expensive

than a typical 16-foot straight edge, they often claim to reduce costs over the long term. Using a physical straight

edge is also sometimes criticized as being manpower intensive because profilers are faster. However the projected savings of profiling devices can quickly disappear

if your customer argues over the accuracy

of the test results. The statistical data and graphical displays from a profiler are often not always so easy for

many customers to understand. The disputes created by these magical black boxes on wheels

may cause additional costs when more meetings, negotiations, travel expenses, re-testing, penalties, and delayed

payments are considered. |

|

| |

|

|

|

|

|

| |

Roughness is so much easier for customers to see when

using a straight edge by just looking

at the gap between straight edge and the runway.

The gap can easily be measured by using shim gauges marked with the size and recorded. The straight edge test results

are very accurate and hard to dispute unless the straight edge used was not qualified. |

| |

|

|

|

|

|

| |

To insure repeatable results in this hostile environment,

profilers also require careful use or

frequent maintenance. If normal industrial standards were applied to profilers, they would also require periodic

calibration to a NIST reference.

The complexity of these profiler systems usually require highly trained personnel where a minimum wage employee

could operate a straight edge. Even the slowest worker using a straight edge, can usually keep up with the fastest

paving machine. |

| |

|

|

|

|

|

| |

Screeds are not Good Straight Edges |

| |

The majority of asphalt and concrete contractors often

use a "Screed"

as a straight edge to check paved surfaces for roughness. Screeds were designed to work concrete and should not

be used as a straight edge because their straightness is unknown. New screeds taken out of the box failed to meet any reasonable quality standard for a measurement tool. |

| |

| |

|

|

|

|

|

|

|

After checking (4) new 16-foot aluminum screeds from

two leading suppliers, each were found to have major flatness errors by as much as 0.069-inch. The screeds were also twisted and deflected by as much as 0.056-inch when end supported. These inspection results show that a

contractor using a typical screed to check pavement roughness could be using up almost half of the 0.25-inch tolerance

specified by the FAA with the combined 0.12-inch screed error. Good pavement could be rejected

by a customer because a contractor used one of these typical screeds for runway inspection. |

| |

|

| |

|

| |

| |

| |

|

|

|

|

|

| |

Straight Edge Specifications for

Runway Inspection |

| |

Have you ever noticed how most other companies never

mention what sort of flatness and straightness quality they supply with their straight edges? It's also amazing

that neither the FAA nor USAF specifies

any edge quality or certification requirement for straight edges. It should be very important, at least to the paving contractor, before they are stuck

with a batch of rejected pavement. |

| |

|

|

|

|

|

| |

The USAF indicates the following 12-foot straight edge

requirements in ETL09-2 section 220.3.2.6.

"Straightedges shall be constructed

of aluminum or other lightweight metal and shall have blades of box or box-girder cross section with flat bottom

reinforced to ensure rigidity and accuracy. Straightedges shall have handles to facilitate movement on pavement". The PaveFlat units are constructed from an aluminum

box extrusion that includes grips. The FAA does not specify any type of straight edge design beyond the 16-foot

length required in AC 150/5370-10E. |

| |

|

|

|

|

|

| |

The FAA does however require calibration standards

for other aircraft inspection tooling as specified in AC 145-9 (4-12, p.53) that include procedures and records required for repair stations. Although these FAA standards were not specifically designed for runway

maintenance tooling, they embody good practices that are common to ISO/DIN standards

found in industry. |

| |

|

|

|

|

|

| |

Europe has specified its very own standard for straight

edges that also requires the use of a special taper gauge capable of measuring up to 1-inch of runway surface deviation

under the straight edge. European Standard EN 13036-7 of August 2003 for Road and airfield surface characteristics

test methods includes a specific requirement for 3-meter long straight edges: "The straightedge shall be (3,000 ± 3) mm and of rigid construction such that

when suspended at the end points its measurement edge shall not deviate from a true plane by more than ±0,5

mm at any point. The straightedge shall also be straight along its length and shall not deviate from straight by

more than 1,5 mm. The horizontal width of the measurement edge shall be (25 ± 1)" mm." This specified EN13036-7 flatness tolerance of ±0.5

mm (±.019-inch) allows a permissible

error of 0.038-inch which is over 30%

of the 1/8-inch runway surface smoothness deviation requirement. |

| |

|

|

|

|

|

| |

It seems more reasonable that a typical industrial

gauge specification of 10% of the

tolerance range would be an appropriate standard

for the runway straight edge quality. Using this criterion, the standard flatness and straightness tolerance for

a FAA 16-foot straight edge should be 1/4-inch. Since military and some regional or international specifications

use a tighter 1/8-inch standard for checking pavement, a reasonable tolerance for straightness and flatness would

keep deviation at less than 0.012-inch.

To meet normal industrial gauge standards, the straight edge should be traceable to a NIST surface, include a serial number, and certification. This precision straight edge should

be re-inspected at specified intervals to assure that it has not been damaged and record or fix any errors found. |

| |

|

|

|

|

|

| |

Straight Edge

Tolerance = 0.012" total error

|

| |

|

|

|

|

|

| |

PaveFlat Straight Edges are Designed

for Contractor Use |

| |

A straight edge used for checking pavement must have

a wide enough base to stand on the edge without out falling over. The unit must not rust or be susceptible to damage

with normal use. |

| |

| |

|

|

|

|

|

| |

The straight edge must be light enough for one person

to lift and handle. Steel is too heavy because a 16-foot x 4-inch x 1-inch straight edge weighs 217 pounds and

certainly exceeds NIOSH lifting

limitations as published in 94-110.

Aluminum extruded alloys offer light weight, but the extrusion process can twist the beam and the soft edge nicks

easily. Bonding a continuous stainless

steel edge to an aluminum box extrusion substrate provides durable non-rusting working edge. Adding location pads to the opposite side allows precision

grinding each side to remove any surface errors on the useable edge. Handholds are then bonded to the sides of

straight edge to make the unit easy to grip. |

|

|

| |

|

| |

|

| |

| |

| |

| |

|

|

|

|

|

| |

|

Next the straight edge is checked against a precision

NIST qualified granite surface plate using our inspection procedures. The flatness and straightness measurement is recorded on

the Inspection

Certificate that references a unique

serial number marked on the unit. If you ever suspect that your straight edge has been damaged,

we can also recertify or repair your straight edge. |

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| |

PaveFlat-16 straight edge for checking pavement smoothness |

|

| |

- Overall Size: 16-feet x 4.1-inch x 1-inch

- Stainless Working Edge: 192-inches x 1-inches

- Straight Edge Weight: 33 lbs.

- Flatness and Straightness: 0.012-inch maximum deviation over 192 inches

- Complies with FAA advisory circular AC 150/5370-10E

of September 2009

- Serial number marked on unit for traceability

- Certificate of inspection included

- Cost: $2,500 each.

- Freight additional - FOB Springfield, OH

- Shipment 1 to 2 weeks ARO

|

| |

|

|

|

|

|

| |

PaveFlat-12 straight edge for checking pavement smoothness |

|

| |

- Overall Size: 12-feet x 4.1-inch x 1-inch

- Stainless Working Edge: 144-inches x 1-inch

- Straight Edge Weight: 25 lbs.

- Flatness and Straightness: 0.012-inch maximum deviation over 144 inches

- Complies with USAF specifiation ETL09-2 section

220.3.2.6 of March 2009

- Serial number marked on unit for traceability

- Certificate of inspection included

- Cost: $2,250 each.

- Freight additional - FOB Springfield, OH

- Shipment 1 to 2 weeks ARO

|

| |

|

| |

PaveFlat-10 straight edge for checking pavement smoothness |

|

| |

- Overall Size: 10-feet x 4.1-inch x 1-inch

- Stainless Working Edge: 120-inches x 1-inch

- Straight Edge Weight: 21 lbs.

- Flatness and Straightness: 0.012-inch maximum deviation over 120 inches

- Serial number marked on unit for traceability

- Certificate of inspection included

- Cost: $2,125 each.

- Freight additional - FOB Springfield, OH

- Shipment 1 to 2 weeks ARO

|

| |

|

|

|

|

|

| |

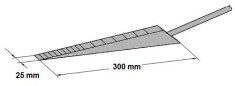

PaveFlat-3M straight edge for checking pavement smoothness |

|

| |

- Overall Size: 3000 mm x 104 mm x 25 mm

- Stainless Working Edge: 118.1-inches x 1-inch

- Straight Edge Weight: 21 lbs.

- Flatness and Straightness: ± 0.019-inch maximum deviation over 118.1-inches

- Complies with EN 13036-7 specification of August

2003

- Serial number marked on unit for traceability

- Certificate of inspection included

- Cost: $2,500 each.

- Freight additional - FOB Springfield, OH

- Shipment 1 to 2 weeks ARO

|

| |

|

|

|

|

|

| |

Shim Gauge |

|

|

|

| |

- Set of 5 pcs of - 12 x 1 x 1/16" with top

cover

- Simple feeler type gauge

- Made from composite 1/16" thick plastic strips

- Weight: 0.2 lbs.

- Used to quantify amount of runway deviation

- Cost $125.00 each

- FOB Springfield, OH

- Shipment: 1 week ARO

|

|

| |

|

|

|

|

|

| |

Taper Gauge |

|

|

|

| |

- Taper gauge per EN 13036-7

- Marked with 1 mm and 10 mm increments

- Made from Aluminum

- Weight: 0.8 lbs.

- Used to quantify amount of runway deviation

- Cost $500.00 each

- FOB Springfield, OH

- Shipment: 1 to 2 weeks ARO

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

We Acccept Credit

Cards

|

|

|

|

For More Information Contact: |

| Mike Petsch & Associates, Inc. |

Phone (937)438-8031

|

| P.O. Box 684 |

|

Tipp City, OH 45371

|

Email donpetsch@gmail.com

|

| |

|

|

|

PaveFlat.com

|

|

| |

|

|

|

|

|